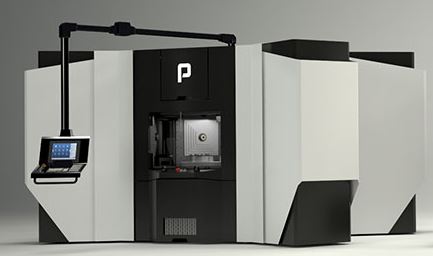

After the success of the 3SPINDLES machine, I present the new 5SPINDLES refreshed according to the latest developments developed on our warhorse, the MULTICENTER 3SPINDLES.

The basic concept remains that of the 3SPINDLES, that of FLEXIBLE PRODUCTION, ie a FLEXIBLE machine equivalent to many machining centers, with the advantage of being contained in a single machine in order to get advantages that many individual machines cannot offer, such as:

- LESS OCCUPIED AREA

- LESS ENERGY CONSUMED (one hydraulic unit, one swarf conveyor, 1 robot VS many robots)

- LESS COSTS FOR AUTOMATION (1 robot VS many robots)

- LESS TIME TO RE-EQUIP (multiple fixture positions on machining centers)

- LESS COSTS OF FIXTURE

- LESS WASTE (one production process VS many production processes CPK, etc.)

- LESS TIME FOR RUNOFF APPROVAL (with many positions you have to wait for the approval of the quality for each positioning before producing)

- LESS TOOLS IN DEPT. (with many machines you need a lot of tools)

ALL THESE “LESS” ARE HIDDEN WASTE IN YOUR PRODUCTION DEPARTMENT THAT YOU CAN REMOVE FOREVER!

FLEXIBILITY, AT THE SAME TIME PRODUCTIVITY, AND, AS BONUS, THE ADVANTAGE OF HAVING A SINGLE MACHINE!

This new machine has acquired all the innovations developed on the 3SPINDLES so it shares a unique project platform, that means: the whole experience started from 2005 up to now, better known as technological know-how.

A NEW MACHINE BUT WITH PAST ORIGINS

In fact, apart from the structure of the machine frame, all main elements are in common as:

- 3-AXIS CNC MODULE

- TOOL CHANGE AND MAGAZINE WITH CAPACITY FROM 60 TO 200 TOOLS

- SATELLITE TABLES (CONTINUOUS FOURTH AXIS)

- CNC PALLET CHANGE WITH HIRTH CROWN

- CNC, DRIVES AND SIEMENS CONTROL 840D SL OR FANUC 31i

- POWERFUL USER INTERFACE WITH NEW GENERATION SYNOPTIC

ALSO THE AESTHETICAL ASPECT WAS DEVELOPED WITH THE SAME FAMILY FEELING

In addition to aesthetics, the same concepts were applied for rapid communication to the operator through LED strips, as was already done for 3SPINDLES. These strips are positioned on the front of the machine, but also around the various access windows so that the operator ALWAYS knows the machine status.

Another fundamental concept transferred to the 5SPINDLES is the accessibility to the maintenance areas in order to better perform the PREVENTIVE MAINTENANCE quickly and easily.

TO WATCH THESE POINTS SUMMARED IN A REAL VIDEO INSERT YOUR MAIL AND GO DIRECTLY TO THE VIDEO.

Maurizio Porta

Expert in Flexible Production

Ita

Ita Deu

Deu