Working with a production department means dealing every day with a lot of numbers that need to be carefully kept under control.

However, the main question is always the same:

“Which are the most important values to consider?”

So you need to identify which parameters and numbers you have to keep under control and which instead can be left out, because they would just be a waste of time.

I’m the first to admit that not all indices are always vital. Nevertheless, your production department needs to understand what it should focus on.

An interesting lesson I learnt during more than 25 years of experience in the sector is that not all production managers have the same approach towards numbers.

Speaking of Machine Tools, there are companies that only focus on financial indices.

I have worked with managers who use the EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortisation) to assess investments in new plants and machinery.

At the same time, there are companies far more focused on cycle time, as they believe it is the only key information on which they will base various decisions – especially strategic ones.

In the latter case, these are mostly manufacturers dealing with large job orders for substantial production batches. This means they need to achieve very fast cycle times and often have to reduce their profit margins to stay competitive and take away orders from rival companies.

Otherwise they’re out of the market!

This is an emblematic expression on how we should approach numbers:

“We should always keep in mind that numbers are just a simplification of reality.”

Numbers just provide a picture of reality, what it looks like at a given time.

The ability of people and, in our sector, of an entrepreneur and production manager is to take these numbers, reality, and try to interpret them as best as they can.

What makes the difference for our company is how we interpret values and numbers and this also makes us more competitive on the market in the long term.

So the question I’d like you to consider is:

“Is it better to focus your attention on the cycle time or on the cost per part?”

According to my own personal experience, the COST PER PART is the only value you need to learn how to master and that contains, along with other numbers, the cycle time as well.

This is what I teach with the PORTA Production Method.

The real problem is that these 2 values are very often mixed up.

Many insiders think that the cycle time is the real value that determines the final cost per part of components.

BUT THAT’S NOT THE CASE!

If the cycle time is not the real number that makes the difference, which are the parameters you should really be considering?

How to determine the COST PER PART

of the components to be processed

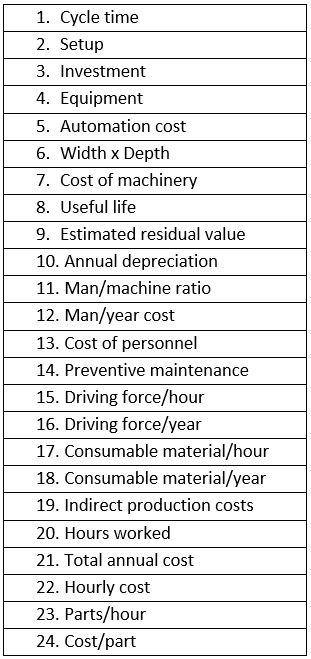

Below is a table that will help you in your reasoning, so you’ll be able to turn your attention to the only value that really matters, i.e. the real cost of each part coming out of your machine.

Here is the table to calculate the cost per part:

As you can see, the CYCLE TIME is just one item, the first one. This means it is certainly one of the most important, but not the only one.

There are many other cost items worth considering, like:

- Setup times

- Investments

- Automation cost

- Cost of equipment

- Cost of the machinery

- Annual depreciation

- And many other items…

This is exactly where the problem lies: too often I provide professional advice to companies for whom the only important value is the Cycle Time, while I strive to teach them to focus on the COST PER PART.

When I provide professional advice, my team and I help the entrepreneur and production manager to think based on a wide range of numbers, which help us compare several plant options.

Is it better to have a Machining Center or a 3-spindle Machine Tool?

Why is the PORTACENTER often the most suitable solution?

How can I get my production company to achieve a higher profit margin?

It depends on a series of factors, which once connected to each other will lead you to identify the right calculation of the COST PER PART.

This is the only value that will help you make the difference.

This is the value that the most competitive companies use to beat market competition.

Clearly this requires thorough study, also to get to be able to think more accurately and build a better PRODUCTION STRATEGY, one that is designed around your company.

A production strategy that takes everything into account.

However, to do this it is essential to have right by your side an expert who can really help you find the best solutions for your company.

An unbiased external point of view able to guide you through levels of reasoning that are extremely difficult to reach while dealing with the countless daily commitments that the company and production department have to face.

And this is the role of the Technical Tutor.

An expert in this sector who has used Machine Tools for metalworking for over 20 years and who now is available to help production departments increase their performance.

You can either keep on focusing on the wrong values, like the cycle time, or you can finally take the reins of your production company and become more competitive!

Are you ready to make a difference in your production department?

ASK FOR A DIRECT CONSULTATION with one of our Technical Tutors.

Send an email to porta@flexible-production.com for further information.

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Ita

Ita Deu

Deu