CNC Machining Centers: how to take a technological leap and face the change

The world of Machine Tools has always been dominated by 2 main categories of machinery.

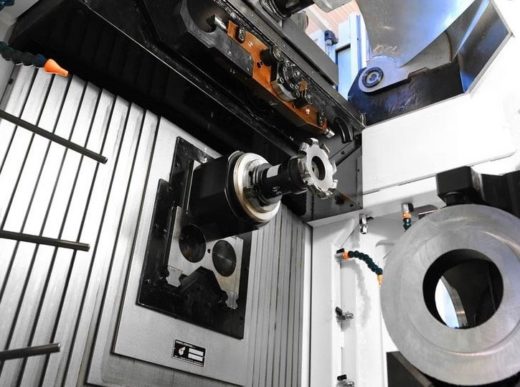

On the one hand, the Machining Centers, very flexible machines, which help companies manage small production batches.

On the other hand, the Transfer machines, designed to drastically increase productivity and meet the growing demand for supplies of large lots.

These models, that are complet

Ita

Ita Deu

Deu