The production of valves includes a wide range of sectors and components, but in this article we will focus on STEEL and CAST IRON valves.

Why do I want to focus on these two materials?

Because, if you think about it, until now their traditional production process has always been divided into two main phases:

- TURNING

- MILLING/DRILLING

In my many years of experience working with various companies that use Machine Tools, I have visited production departments where the first phase is usually carried out on a horizontal lathe for small valves and on a vertical lathe for larger valves, and then, in the second phase, a smaller or larger machining center is used, again depending on the size of the valve to be machined.

These two phases are carried out with two types of Machine Tools, lathe and machining center.

But in order to produce in bulk and increase productivity, I have also seen production situations organised as follows:

- Lathe 1: Turning of first flange

- Lathe 2: Turning of second flange

- Lathe 3: Turning of third flange

- Machining Centers 4, 5 and 6: Milling

- Drills 7 and 8: Drilling of flange holes

- Drills 9 and 10: Tapping of flange threads

- Valve manual deburring department

But now let’s get to the point…

WOULDN’T IT BE NICE TO HAVE JUST ONE MACHINE THAT YOU PUT

THE VALVE IN AND IT COMES OUT 100% FINISHED WITH ONLY ONE PROCESS?

It really would be nice, wouldn’t it?

Because the real difficulty is that with a production where machines are in series and each one performs only one phase, a lot of problems arise.

Do you want to know what happens?

HERE ARE 8 CRITICAL PRODUCTION POINTS

WHEN MACHINING A PART WITH MULTIPLE MACHINES AND PROCESSES:

- Quality problems caused by having to reposition the part on the various machines.

- Personnel costs, which are obviously high, because you have to employ more people on the line.

- Greater incidence of the “human” variable, which means production “inconsistency”.

- Many people = many management problems over 3 shifts.

- Much more space taken up than actually needed.

- High part handling, leading to a greater likelihood of creating defects on parts and costs associated with poor process optimization.

- WIP (Work in Progress) chain too long, difficult to control,

with too many parts stopped during the various phases. - Automation, very complicated and too expensive.

WHICH ARE THE CONSEQUENCES FOR YOUR PRODUCTION WITH THE

PROBLEMS LISTED ABOVE?

Unfortunately, the problems related to the 8 aforementioned points are many.

The first, and most recurrent, is a high percentage of customer complaints concerning the poor quality of parts.

Undoubtedly, with this long chain of machines arranged in cascade one after the other, it is difficult to produce quality parts made to specifications and free of burrs.

We all know that when a customer is unsatisfied, the days become tougher, and on a market that is increasingly smaller and more saturated, there are many other companies ready to take care of a customer looking for alternatives.

Do you want your customers to be stolen because of poor process efficiency?

I don’t believe you do!

Now let’s move onto the cost of personnel.

This topic is also extremely critical, not only because personnel costs literally weigh heavily on the part, but because today the more workers directly involved in the production process, the higher the probability of human error. (If it’s called “human error”, there is a REASON for it: we are only human!)

Furthermore, the more personnel we have, the more difficult and costly it will be to keep them up to speed and trained in all the various aspects required by today’s increasingly numerous and restrictive regulations.

Do you want some examples?

We are talking about operational training, workplace safety training, personnel management, with holidays, sick days, personal leaves of absence and so on.

The list is really long and will become longer and longer.

Nowadays, the space taken up by systems has an important value, and therefore a cost, which should at least be quantified.

With so many machines, industrial accounting also has to consider the space taken up by the system, as it is associated with costs such as building insurance, heating, lighting, property taxes, etc.

If we then analyse the WIP, in other words the material standing between one processing phase and the next, between different machines arranged in a chain, partially processed parts have a tendency to accumulate and, sometimes due to human error, they skip one phase and reach the assembly department (or, even worse, the end customer) not made to specification, causing problems that we all know very well.

And what if we decide to automate these machines?

It is easy to see that the more machines there are, the more robots and conveyor belts will be required, leading to high automation costs and substantial complexity.

Another key point is part or size changeover.

Retooling takes a very long time, so this results in a major loss of competitiveness which plays into the hands of competitors.

BUT THEN THE QUESTION NATURALLY ARISES…

HOW CAN ONE BECOME MORE COMPETITIVE?

THE SOLUTION IS:

INTRODUCING THE NEW PORTACENTER 500

WITH TURNING STATION!

A single Machine Tool performs all the above operations, all requiring just one person.

Furthermore, an end-of-process part check can be introduced to ensure that all phases have been carried out smoothly.

And again, the final check can be integrated into a system based on the INDUSTRY 4.0 model, where a unique serial number is generated for each valve produced.

This way, valve data is archived, creating digital traceability for each component produced.

If necessary, you can simply scan the QR CODE with any smartphone at a later date to check all the valve construction data, thereby offering the end customer an EXCEPTIONAL service.

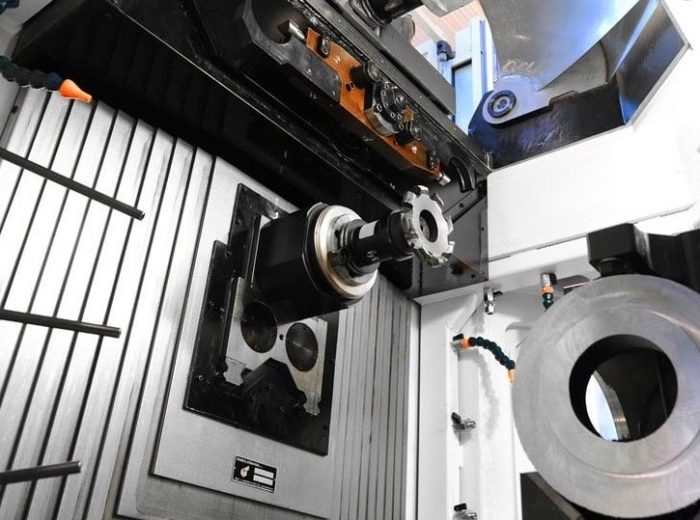

Following the phases carried out on the PORTACENTER 500, here is an example of a process:

- STATION 1: MILLING

- STATION 2: TURNING OF FLANGES

- STATION 3: DRILLING/THREADING OF FLANGE HOLES/DEBURRING/INTEGRATED QUALITY CONTROL

- STATION 4: PART LOADING/UNLOADING (while the machine is working!)

As you can see, the valve execution time is divided between the 3 independent work stations, maintaining a single process.

The valve is clamped only once and it is completely finished, with no re-clamping required, to the full benefit of processing accuracy.

A SINGLE PORTACENTER 500 PRODUCES LIKE MANY MACHINING CENTERS, BUT WITH THE FOLLOWING 11 ADVANTAGES:

- Reduction of labour costs > only one operator required instead of several.

- Fewer “human” variables = fewer errors > significant scrap reduction.

- Fewer workers = fewer problems in managing them > better training.

- Less space taken up and less handling of parts > cost cutting.

- Short WIP chain, easy to control.

- Simplified and cheaper automation > 1 machine instead of several.

- Lower cost than Machine Tools.

- Lower energy consumption.

- Less expensive equipment > 3-4 machines with pallet change have 6-8 pieces of equipment, while the PORTACENTER only has 4!

- Faster production, thanks to less downtime and less tool change and pallet change.

- Much faster production changes to fulfil market demands and reduce stock!

HERE IS THE PORTACENTER 500

I WOULD LIKE TO BE 100% CLEAR AND TELL YOU THAT

THE PORTACENTER 500 IS NOT THE SOLUTION FOR ALL VALVES!

Yes, you read that right.

In fact, it might seem an EXCELLENT concept for all valves, but it isn’t.

The PORTACENTER 500 is specifically intended for the following valves:

- GATE VALVES

- GLOBE VALVES

- CHECK VALVES

- PLUG VALVES

- BALL VALVES

- CONTROL VALVES (SIZES FROM ½” TO 4”)

- BUTTERFLY VALVES (UP TO 12”)

WARNING!!!

IN WHICH CASES SHOULD YOU NOT BUY THE PORTACENTER 500?

The PORTACENTER is not the right solution for larger valves, because the larger the valve, the less amount there is to produce, so this type of machine would not be competitive.

More specifically, the opposite is also true: THE SMALLER THE VALVE, THE MORE AMOUNT THERE IS TO PRODUCE, so this route may not be ideal, unless you are aiming to produce what you sell with no stock.

THE PORTACENTER 500 IS PERFECT

FOR ½” TO 4” GATE, GLOBE AND SIMILAR VALVES AND BUTTERFLY VALVES UP TO 12”.

WHY THESE DIMENSIONS ONLY AND NOT THE ENTIRE RANGE?

The explanation lies in the fact that in the range from ½” to 4” for GATE, GLOBE and similar valves as well as in the range of BUTTERFLY valves up to 12”, the competition is tougher.

So a fast and competitive machine is needed, a machine that is designed for top performance in the 4” to 12” range, because if a company is not competitive in this range, it is in for a beating and, in a short time, this company might even go bankrupt, crushed by the price war!

In the range above 4”, volumes are drastically reduced and it no longer makes sense to build a machine with parallel operations.

So in this case, machines with a single-spindle and turning ability become once again a proper choice.

So you can understand that each individual situation should be assessed in order to make the right choice and achieve the best result.

Proof of what you have just read lies in the fact that this very competitive segment with high production volumes is doing away with single-spindle machines too, since it would be necessary to install more machines with respect to the number of valves to be produced.

HOWEVER…

More machines = all the problems listed above.

ARE YOU READY TO CUT PRODUCTION COSTS

AND IMPROVE YOUR PROFIT MARGINS FOR VALVES FROM ½” TO 4” AND BUTTERFLY VALVES UP TO 12”

THANKS TO THE PORTACENTER 500?

Here is a processing example:

2” GATE VALVE: 119 seconds (2 minutes)

10” BUTTERFLY VALVE: 320 seconds (5.3 minutes)

NOT YET CONVINCED OF WHAT I HAVE SAID SO FAR?

THEN READ THE CASE HISTORY OF A CUSTOMER WHO CHOSE THE PORTACENTER 500 SOLUTION!

THE CUSTOMER SPEAKS…

Kimray is a private stock company that produces a range of pumps and control valves for the oil industry. These parts, made of both steel and iron, vary from 1” to more than 36”.

The overall volume of parts produced by Kimray has almost doubled in recent years.

This production increase mainly concerns parts belonging to the smaller range with quality finishing requirements. This is the product range on which Kimray has focused its efforts in order to increase its processing

capacity.

In Kimray’s case, the wide range of offers, the ever increasing volumes and the Just In Time company philosophy required a processing cell with high PRODUCTIVITY and high FLEXIBILITY, as well as great care and accuracy in complying with their demanding quality requirements.

THE INTEREST IN THE PORTACENTER

After a complete and careful survey of the Machine Tools available on the market, Kimray found the PORTACENTER to be particularly interesting.

The PORTACENTER is a machine equipped with three four-axis processing modules, each one with excellent tool storage capacity and a central rotating table.

In addition to being a very fast machine (with a yield comparable to four horizontal machining centers), the PORTACENTER is designed to process heavy iron materials, necessary for the parts produced by Kimray.

One of the unique characteristics which attracted this company’s attention is the ability to process different parts at the same time, through the cell.

Thanks to this method, with annual lots of 1,000 parts or fewer, Kimray can take advantage of the low cost of this machine, without adding long set-up times and tooling costs.

The fact that the PORTACENTER, controlled through FANUC CNC, is a standard product for PORTA, is highly appreciated by Kimray.

Even the integrated diagnostics system via the Internet was considered a strength. Although the machine can be automatically loaded, Kimray’s plan was to operate the machine with manual loading: the operator area is well-protected, just like the fencing with dry floor since there is no spraying of lubricant or coolant.

All of these were key elements when choosing the machine.

PRODUCTION RESULTS

Seven months after the Machine Tool was installed, Kimray discovered that, thanks to the PORTACENTER, it is able to produce much larger quantities compared to those estimated at the time of purchase and also compared to the assessments that justified buying the PORTACENTER.

Using the universal tool concept, the cycle time is eight times faster than the cycle time obtained with traditional machining centers.

At the same time, the set-up is simple and fast. The part change times are no more than 2 hours and even the initial machine set-up for a new part, even if complex, is carried out faster.

THIS MACHINE IS ABLE TO PRODUCE AT RATES WHICH ARE MUCH FASTER COMPARED TO COMMON MACHINING CENTERS.

Indeed, this 3-spindle system has allowed Kimray to do work internally that was previously outsourced, thus achieving better process control and also managing to handle smaller lots in favour of reduced stock on hand.

The PORTACENTER has satisfied and exceeded Kimray’s expectations and has become an important piece of equipment for the company in terms of continuing to offer high-quality and competitive products from the price standpoint.

HERE IS A REAL-LIFE TESTIMONIAL ON USE OF THE PORTACENTER

High-pressure steel valve 2” TAPERED – it used to take 306 seconds to make on a horizontal machining center – now it can be done in 156 seconds with the PORTACENTER.

Now try to answer these 3 questions. Take 10 minutes of your time and write your answers on a piece of paper; this is very important, writing is difficult because it requires concentration, that concentration that we often do not have for lack of time, and that however makes us make the wrong decisions or, even worse, not make any decision at all.

WHAT WOULD CHANGE IN YOUR COMPANY BY INSTALLING A PORTACENTER?

WHAT WOULD HAPPEN AT YOUR COMPANY IF YOU CARRIED ON INSTALLING TRADITIONAL MACHINERY?

WHAT WOULD HAPPEN TO YOUR COMPANY IF YOU DID NOTHING AND SIMPLY POSTPONED YOUR DECISIONS?

I REMIND YOU THAT…

IT IS NOT THE STRONGEST OF THE SPECIES TO SURVIVE BUT THE ONE WHO IS ABLE TO QUICKLY ADAPT TO NEW SCENARIOS!

These are important issues for a production department, which cannot be neglected in any way if you want to have a successful company that can thrive in the future.

Do you work in the sector of CNC Machine Tools for metalworking and are you curious to understand what would change in your production department by applying a specific Preventive Maintenance system?

Get in touch now to request your FREE consultation with one of our TECHNICAL TUTORS.

Send an email to porta@flexible-production.com for further information.

To learn more about Competitive Production

and Flexible Production

CLICK HERE

>>> www.flexibleproductionbook.com <<<

My book dedicated to users of Machine Tools for metalworking who want to make the leap in quality, is waiting for you!!!

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Ita

Ita Deu

Deu