One of the statements I hear from many companies is “I want to become the Number 1, the market leader”.

Maybe, in that moment, they are not the NUMBER 1 yet, but their aim is to be a leader in the sector and this leads them to observe the market proactively, making them more inclined to challenges and changes.

They feel they have to work hard to face change and aim high with their production companies.

I don’t mind telling you that when I meet this kind of company I am fascinated and curious, I like to investigate and ask what they think about their competitors, which fixed thought moves their soul and enthusiasm.

I have therefore decided to share with you my 25-year-old experience, visiting successful and non-successful production companies, all over the world, to analyze together what they have in common.

And I can assure you that this clear difference between these two categories of companies exists in every country and culture.

In the world of production, I see too often companies that complain about the market, customers, employees, suppliers, the “thieving government” and so on. Certainly, I recognize that these are variables that influence the way of doing business … no doubt! It is also true that there are other companies that, even with the same variables, manage to be SUCCESSFUL companies!

How could this happen?

Being more interested in understanding these latter companies, how they operate, what they think and, specifically, WHAT THEY DO, I can tell you that the reason why they are successful is that they ACCEPT NEW CHALLENGES.

How?!? First of all, taking a half step forward, into the void. Nothing guaranteed or certified in the result they will get, and that is why they are called CHALLENGES, because the result is NOT certain.

Successful companies take on a higher dose of risk, in order to challenge the principle of inertia that usually stops us.

A sentence I always repeat and that best expresses what I am trying to say is:

“NOT THE STRONGEST, BUT WHO FAST ADAPTS TO NEW SCENARIOS WILL SURVIVE!”

I want to be brief and get to the point.

In the world of production, there are mainly 5 new scenarios and challenges:

- Reduction of stock

- Produce just what you sell

- Flexible production (Time to Market)

- Ease-of-use facilities

- Reduction of investment risk

These 5 points lead you directly to the following benefits:

CUT OF COSTS AND

IMPROVEMENT OF COMPANY PROFITABILITY

How can these results be achieved?

First of all, adopting a very specific method, which helps your production department to have a clear and defined direction and objectives.

Personally, I have always searched for techniques to produce without waste, having one thing in mind: the COST PER PART.

The cost per part (together with the cycle time) is the final figure that allows you to conquer more and more market shares, acquire more customers and enter new sectors, thanks to an efficient production strategy.

For this precise reason, I have studied and developed the PORTA PRODUCTION METHOD, a method that aims for one and only goal: to make you as competitive as possible.

In consulting, production managers and users of Machine Tools often ask me: “Are you a Machine Tool manufacturer or a production method consultant?”.

I answer this question very clearly.

Since 1958, my family has always built Machine Tools, so I am a Machine Tool manufacturer by nature. But if until 2005 we built Machine Tools based on specific customer needs, since that year our goal and our mission have changed.

Being a Machine Tool manufacturer and starting my career in the family business in the early 90s, I had the opportunity to be exposed and deal with many companies and production departments, which over the years have become my passion.

Not so much from the purely technical point of view of Machine Tools, but with regard to the organizational methods that I observed in departments, both in Europe and in the North American market.

Having said that, I began to study the different methods out of pure personal passion, from the first processes to the current and most innovative techniques on the market.

After 10 years of studies and research, in 2015 I decided to publish my first book, titled FLEXIBLE PRODUCTION, which encloses my studies and research in a single Method, specific for users of Machine Tools.

A Lean-style Method, whose goal is to convey a different way of approaching production.

In 2020, after 5 years of implementation of the (mainly theoretical) first Method, I decided to review some steps and to update the concepts previously published.

So I developed the PORTA PRODUCTION METHOD, which is the natural evolution of the first Method.

The PORTA PRODUCTION METHOD contains the main techniques described in the first book, but, of course, with some new analysis.

Many steps have been fixed thanks to the knowledge of the Method applied in production departments and taking advantage of the direct experience of some of my customers who achieved excellent results.

So I can say that the PORTA PRODUCTION METHOD is not just a theoretical approach, but it comes directly from production departments.

So, going back to the original question, if I am a Machine Tool manufacturer or a production methods consultant, from my explanation above you could opt for the second answer.

But this is where it gets good.

Remember that until the 2000s PORTA SOLUTIONS was a company that produced special and customized machines.

Now pay attention to this fundamental step.

Thanks to the FLEXIBLE PRODUCTION Method first and then to the PORTA PRODUCTION METHOD, the PORTACENTER model was born.

What is the PORTACENTER?

It is the first Machine Tool designed for a METHOD, the PORTA PRODUCTION METHOD.

So, now I am no longer a manufacturer of customized Machine Tools, but I am the manufacturer of a Machine Tool designed to enhance the PORTA PRODUCTION METHOD.

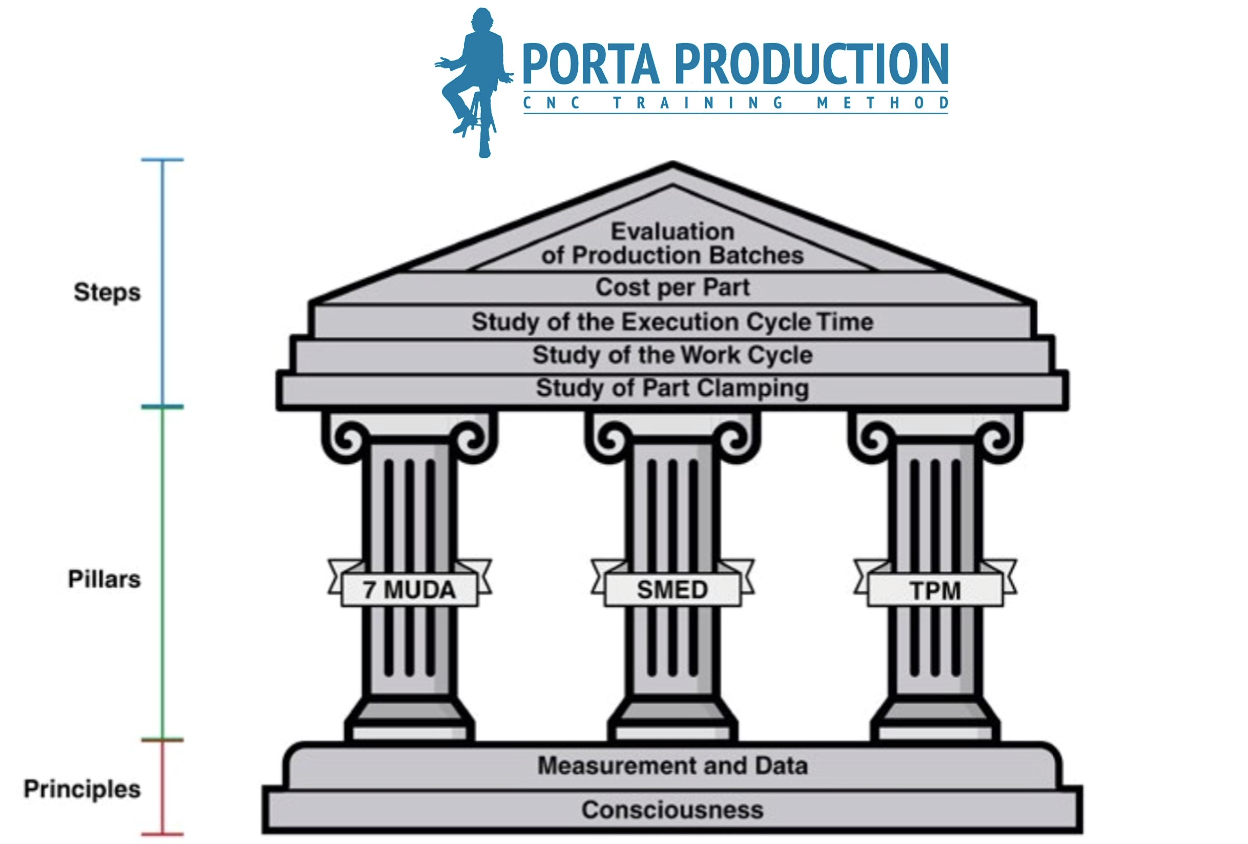

The PORTA PRODUCTION METHOD can be adopted even if you do not have the PORTACENTER. If you have already read my book, you know that at the base there are:

- 2 principles

- 3 pillars

- 5 steps

Nowhere you will read that you need the PORTACENTER to do something.

The strength of the Method is that, in the production industry, it can be adapted to any production department and Machine Tool, even to classic Machining Centers.

And the good news is that it will bring you good results.

Having said that, if you then install a PORTACENTER, you will see how the PORTA PRODUCTION METHOD will be much easier and faster to implement, because the 3-spindle PORTACENTER has been designed just for this.

Following the 3-spindle philosophy.

The opposite is even true: if you install a PORTACENTER and start using it, without realizing it, you will adopt some of the PORTA PRODUCTION METHOD behaviors.

Returning to us, certainly getting involved and evaluating new production methods for your company requires commitment and it often happens that:

- you don’t have time;

- you don’t find the right concentration;

- the thought of new investments scares you;

- you pretend not to see.

This is why it is important to discuss with those who have spent a lot of time examining new production contexts and studying new production methods suitable for the ever-changing world, to then merge them in order to provide innovative solutions.

Because there is a big difference between those who want to find a solution (and are willing to listen to) and those who give up and pretend nothing has happened, with the belief that there is nothing better.

I know very well how it works and now I’ll list the most common excuses we tend to resort to.

“The machines, even if they are old, still work”.

“I’ve already paid off the cost of my machines”.

“Until my (old and rigid) machines work, I can’t think about anything else”.

“The working environment was better in the past”.

Real commonplaces that unfortunately block the action.

Simultaneously, this mental attitude puts you in a passive state. And this situation can be summed up in one word:

RESIGNATION

If you belong to this kind of company, listen to me:

IF YOU LET YOURSELF BE DRAGGED ALONG BY WHINY PEOPLE, YOU CAN TRASH THIS ARTICLE WITHOUT WASTING ANY MORE TIME!

On the contrary, the customers that use my next-generation Machine Tools (challenging the new market rules) are the furthest away from that kind of COMPLIANT and SAD attitude!

We are talking about entrepreneurs and production managers willing to undertake, namely to do business, for which risk is part of the game. Otherwise you are no longer a company, but you were only in the past. This is why the phrase “The past was better” was born, because at the time you probably took risks, with the right mental attitude, while today you are no longer willing to do it!

So, how can you go back to that situation? Certainly not with thoughts or meditation, but with REAL and CONCRETE ACTIONS, with the desire to call into question and to act, sure that there is a way to cut production costs and improve margins.

I experienced the RESIGNATION phase, too … I admit it.

And I admit that, paradoxically, in some ways in resignation we feel comfortable. There are many people in this situation and this, absurdly, creates a group, a sense of belonging, a general anesthesia based on complaints.

In this paradoxical atmosphere, everyone talks about their ills, clinging to the fact that there is always someone who is worse, or competing for sorrows, like time-wasters.

As I said, at some point it happened to me too and this led me to make wrong decisions, based on savings and driven by FEAR.

But then, thanks to my company team and new investments in more expert personnel, we were able to understand the new market needs, developing the PORTACENTER.

Thanks to this machine, our customers are taking advantage of the wave of the crisis, turning it into OPPORTUNITIES.

These companies have decided to ride this wave, rather than suffer it, while most of them struggle to stay afloat, risking drowning at any moment!

This new machine has found applications from two well-defined sectors.

The first one is that of users of Transfer Machines, who have chosen the PORTACENTER in light of increasing requests of small batches (in order to eliminate stock) and more complex components, with the following consequences:

- longer machine retooling time;

- not enough toolmakers, due to frequent changes;

- more complicated components, continuous production recovery;

- manual deburring phase, therefore unstable final results.

Moreover, complex pieces are more profitable but, due to the above-listed reasons, these margins magically disappear in a flash.

The second group is that of users of common Machining Centers, flexible but not productive, which leads the customer to install even more Machining Centers. This leads to:

- increase in the occupied area;

- need for more manpower or robots;

- higher energy consumption (+50%);

- specific and expensive equipment.

All this results in the zeroing of margins due to high management costs.

THAT’S HOW …

THE PORTACENTER PLACES ITSELF BETWEEN THE TRANSFER MACHINES AND THE COMMON MACHINING CENTERS, GUARANTEEING AN INCREDIBLE COST PER PART!

This machine is in a very interesting area, making the most from the two TECHNOLOGIES. In fact, it quickly adapts to the needs of the market (like Machining Centers), but with high productivity (like Transfer Machines), resulting in a cost per part never seen before!

Moreover, at an economic level, the INVESTMENT RISK is low because:

- it is a standard Machine Tool;

- it is easy to use and to automate;

- it takes up little space;

- it is quickly retooled for any component;

- the retooling cost is very low;

- it is high-productive;

- part reworking are eliminated;

- deburring operations can be easily introduced;

- lower energy consumption.

So, I will NEVER stop stating that you can:

CUT PRODUCTION COSTS AND

IMPROVE YOUR MARGINS

This production way is essential for any company that wants to be on the cutting edge, keep up with the times and be successful, producing efficiently and quickly.

In fact, for a person who wants to do business properly, the success of his company (or the company he works for) is his main goal, so, after a little reasoning, he ACTS and adopts the typical attitude of forward-thinking people.

FORWARD-THINKING PEOPLE WHO, EVERY DAY, DO THEIR UTMOST TO MAKE THAT DREAM COMES TRUTH.

Are you ready to

CUT PRODUCTION COSTS AND

IMPROVE YOUR MARGINS?

All this could happen quickly, in just 2/3 months, thanks to machines produced in series!

Contact us now and ask for a FREE consultation with one of our TECHNICAL TUTORS.

Phone: +39 030-800673

Email: porta@flexible-production.com

To learn more about Competitive Production and PORTA Production Method

CLICK HERE

>>>www.machiningcentersbook.com<<<

My book dedicated to users of Machine Tools for metalworking who want to make the leap in quality, is waiting for you!!!

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Ita

Ita Deu

Deu