Having a strong production company means finding the correct production balance, which maintains the most precise balance between demand and supply.

At the same time, in order to achieve this kind of goal and to obtain a maximization of profit, it is necessary to go for a CORRECT PROPORTION of the Machine Tools in your production department.

If you are focused just on one type of Machine Tool, you will face some risks.

On the contrary, if you make “ALL-IN” on other types of Machine Tools you will have to deal with other risks.

Let’s take an example.

If you have a production department full of Machining Centers in battery, you will certainly have a very flexible structure, but at the same time your company will have high Variable Costs, which will not allow you to create enough margin when demand flows are high.

Basically, you lose speculative and growing periods.

On the contrary, if you have a production department with a prevalence of Transfer Machines, you will be very productive, being able to take advantage of economies of scale. But the operating risk, resulting from the continuous variations in market demand, will make your business model too weak.

In a nutshell, it means that, as soon as there is a sharp decline in demand, you will find you have a very rigid structure and all the gain gathered in the periods of increasing demand will vanish into thin air, in no time.

But let’s see in detail what we are talking about.

DEPARTMENT DISPROPORTION ON MACHINING CENTERS

As already said, having a production department full of Machining Centers in battery could seem smart.

The first thought that would come to my mind is that in this way I have a super flexible structure and I can adapt my production to demand and market variations faster.

But above all, I can contain costs and productivity as soon as market demand shrinks, so that the risk of losing money remains low and restrained.

Variable Costs are costs that vary according to the output produced by the company, which means that the more I produce, the more these costs increase.

At the same time, the less I produce, the more these costs approach zero.

This structure is the one that comes closest to the classic model of Machining Centers in battery.

The main reference Variable Costs are:

- SPACE

- ENERGY

- FIXTURES

- AUTOMATION / PERSONNEL

(Not to mention Fixed Costs)

But let’s see them one by one in detail in order to understand what these costs entail.

- SPACE

Try to increase productivity, aiming to buy more Machining Centers is a bad choice, because soon you will have to expand the building and available space to make room for more machines.

More space = more costs.

This concept is completely NON-economic, because the necessary surface could be greatly reduced and optimized, to create an environment as Lean and smart as possible.

The optimization of spaces is essential to increase the corporate management efficiency.

In practice, we start from a very easy and concrete example.

We consider 3 Machining Centers to support the production of 240 pieces per hour. With 3 Machining Centers, the occupied surface (machines + robots) will be around 240 square meters.

Following a fast growing production line, we would have to face important problems of space.

- ENERGY

The more Machining Centers you put in your department, the more energy they consume, eroding part of the sales margin that the company will be supporting.

The profit margin (or mark up) is essential for any company and it must always be pursued and protected, in order to maintain the company in good health.

In practice, always taking 3 Machining Centers as an example, the energy consumed to produce 240 pieces per hour on average is about 120KW (40.31 x 3 cells).

- FIXTURES

Each Machining Center needs very important, but above all very expensive, fixtures which will affect not only the initial cost, but also the medium-term maintenance cost.

In practice, out of a supposed productivity of 240 pieces per hour, 3 Machining Centers would involve 48 clamps (8 x 2 pallets per single Machining Center).

- AUTOMATION / PERSONNEL

More Machining Centers to keep up with productivity and growing demand, require more specialized personnel, very difficult to find and very expensive today. More and more often, in a way, companies “steal” insiders each other, because they cannot find enough personnel, adequately experienced.

In practice, always keeping as the parameter 3 Machining Centers, the man/machine ratio would be 100%, with a person completely dedicated to 3 Machining Centers, to have a productivity that you can manage with a single PORTACENTER machine and lowering the man/machine ratio to 33%.

The same person would therefore have 67% of the time available to manage other tasks, thus optimizing the production chain.

In this situation, absolutely not easy to face and above all NOT SUSTAINABLE, it is necessary to find a balanced solution that keeps my production department in balance.

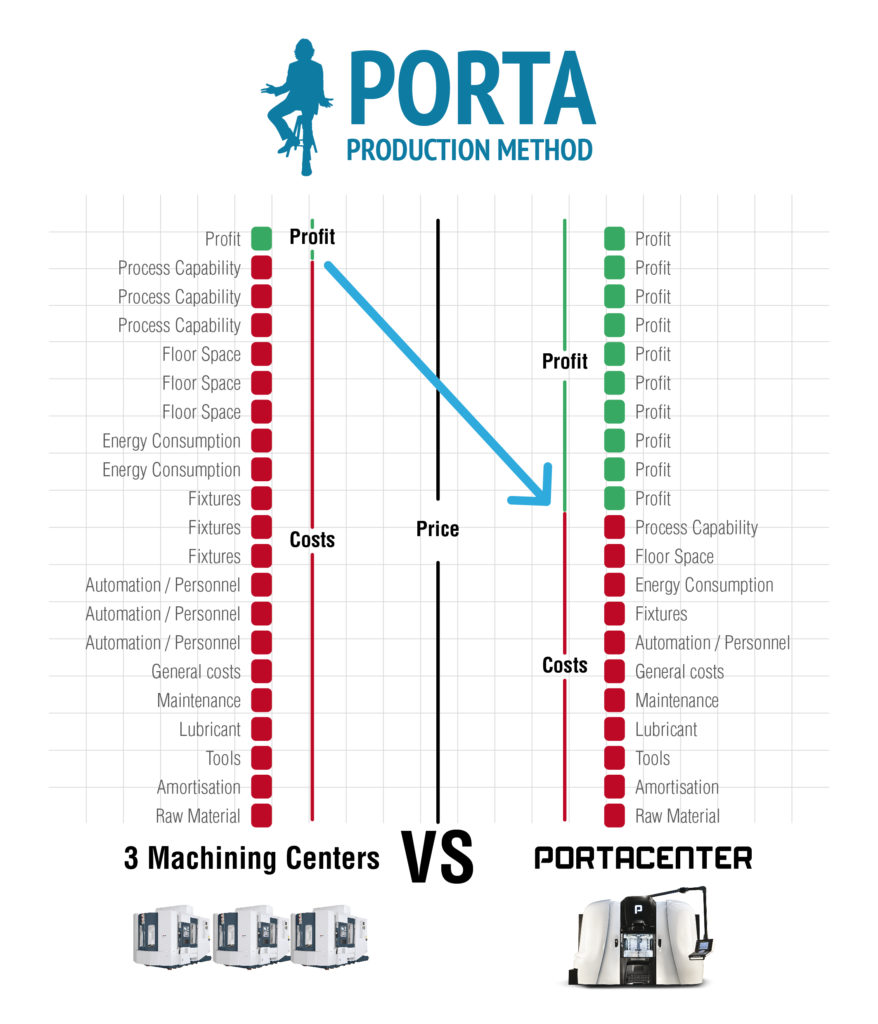

In this regard, in this video you can see the difference between 1 PORTACENTER machine and 3 MACHINING CENTERS in the management of costs, space and fixtures, with the same productivity.

CLICK HERE TO WATCH THE VIDEO.

DEPARTMENT DISPROPORTION ON TRANSFER MACHINES

By virtue of what has been said so far, one would think that the best and immediate solution to make money for a company is to focus on Transfer Machines.

They are very productive, very rigid and able to take advantage of economies of scale.

The answer is: IT DEPENDS.

Often, especially today, even this does not seem to be the correct solution.

And the fact is that it would be a serious mistake to go “ALL-IN” on this type of Machine Tool … now I’ll explain the reason why.

Also in this case, there are some situations in which Transfer Machines can be an excellent solution to support big production batches (increasingly rare), as long as they are kept in a correct machine fleet proportion and logic.

Years ago my company was specialized in the construction of special Transfer Machines (although today we are not anymore).

All this is to say that, for a certain historical period, they were certainly a very good choice for production companies, because we all worked in strongly growing demand contexts.

The best way to support this increasing market demand was precisely to have very productive Machine Tools, capable of managing big production lots and guaranteeing wide profit margins.

The business model based on Transfer Machines is characterized by very high Fixed Costs, also linked to the cost of special machinery, which however are well amortized thanks to low Variable Costs and big quantities for which these machines are manufactured.

They are special Machine Tools, not built in series, produced for a small group of components and for big batches.

The main problem, however, is that when the market demand decreases, today more and more frequently and suddenly, you will risk losing all your earnings in no time.

This is mainly because we are talking about a very rigid structure, almost unable to adapt to market changes.

So, again, in a situation such as that experienced up to the 90s, it made a lot of sense, because the market itself was very slow, having plenty of time to change production strategy.

But, today, we are experiencing sudden, unexpected, aggressive and unpredictable changes, which have raised the operating risk in companies.

A risk that must be managed in advance, in a very clever way.

How?

HOW TO REACH A CORRECT PROPORTION

IN YOUR DEPARTMENT

At this point, you are wondering what the best solution could be to have a balanced department, so that your company can be “almost” totally immune and ready to face strong market changes.

The basic concept is that you have to think as if you were in the investment world.

You cannot go “ALL-IN” on a single asset.

You cannot go “ALL-IN” on one type of action.

The protective shield is the DIVERSIFICATION, that allows you to have competitive advantages in all cases:

- both if the market demand drops significantly

- or it rises a lot.

And to ensure that this gap is kept in balance, what could be the most suitable solution?

Having MULTI-SPINDLE Machine Tools, with independent spindles, which allow you to keep the proper production and department balance.

I repeat, not any multi-spindle machine, BUT:

- with independent spindles;

- running 1 single process.

The PORTACENTER does just that.

In fact, it is a Machine Tool for metalworking, studied and developed in order to fill the gap that many production companies are facing with great effort today.

The PORTACENTER is built following the Lean rules and then developed, in more detail, through the PORTA Production Method.

With this new technology it is possible to have a double benefit:

- IF you are a user of Machining Centers and the market demand increases exponentially, your company will have the ability to progressively support this demand, acting as a bridge with the Machining Centers initially used to manage small batches. In this way you will be able to maximize profits and take advantage of all stages of growth, without losing a big part of margins due to a high increase in Variable Costs.

- IF you are a user of Transfer Machines and the market demand suddenly decreases, you will have the opportunity to reduce the operating risk and keep Fixed Costs lower, thus eliminating losses and keeping margins in production high.

Having a good balance and the right proportion of the Machine Tools fleet is fundamental for any company that wants to continue to be successful, setting great medium and long term goals.

In this regard, our Technical Tutors are working together with many customers in defining the correct balance of their machines fleet, to find the best solution for their specific situation.

For example, with 2 Northern European customers, we are studying a 6-cell solution, which balances 4 PORTACENTERs with Transfer Machines, to better manage the proportion in their production department.

Machining Centers, Transfer Machines or PORTACENTER?

The answer goes around specific studies and department numbers.

Do you want to understand if you are making the most of the production capacity of your production department? Would you like to maximize your production company’s productivity and earnings?

If you are a user of CNC Machine Tools for metalworking and you want to have a clearer and more complete view for the evaluation of your next plant, you just have to contact us.

ASK FOR A DIRECT CONSULTATION with one of our Technical Tutors.

Send an email to porta@flexible-production.com to get more information.

If you want to go deeper on the topics of Flexible Production and Competitive Production

CLICK HERE

>>> www.flexibleproductionbook.com <<<

My book dedicated to users of Machine Tools who want to make the leap in quality, is waiting for you!!!

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Ita

Ita Deu

Deu