On October 29th, 2019, in Villa Carcina, the “Smart Factory and the Application of Qualifying Technologies” Tour took place in a collaboration between Porta Solutions S.p.A., Studio Base Consulting & Training and The Arts & Crafts Technology Center.

A training session for 24 operators, including managers, engineers and entrepreneurs, on issues related to Lean Manufacturing and Industry 4.0.

A Tour within the training course “Mastery Industry 4.0”, strongly recommended by the promoters to support the theoretical study with real cases of companies like ours, which really apply these techniques first hand.

This path and Tour were tied to the practice of how to apply the tenets of Industry 4.0 to reality.

And what better chance to show

who is implementing these techniques in their company?

In Porta Solutions, we decided to organize this Tour in a strategic way, developing the first part on a theoretical lesson, held by me, on Industry 4.0 and with a real analysis of the results we are reaching in our working environment.

The case study was focused on the

3-spindle MULTICENTER Machine Tool

This was our test bench on which we could test the concepts of artificial intelligence in collaboration with the human being.

After this first part in classroom, the Tour moved to the Assembly Area, where we experienced firsthand what was learned before.

Industry 4.0 and MULTICENTER explained in the classroom

As mentioned, the first part of the Tour with Studio Base was focused on the analysis of the results obtained with the application of the Industry 4.0 techniques on the MULTICENTER.

In this phase, we debated several important issues in order to learn more about Industry 4.0:

- the Industry 4.0 Research and Development program;

- the 3-spindle MULTICENTER Energy Characterization;

- the aims of the Energy Research;

- the Average Cost per kwh;

- the ecological footprint;

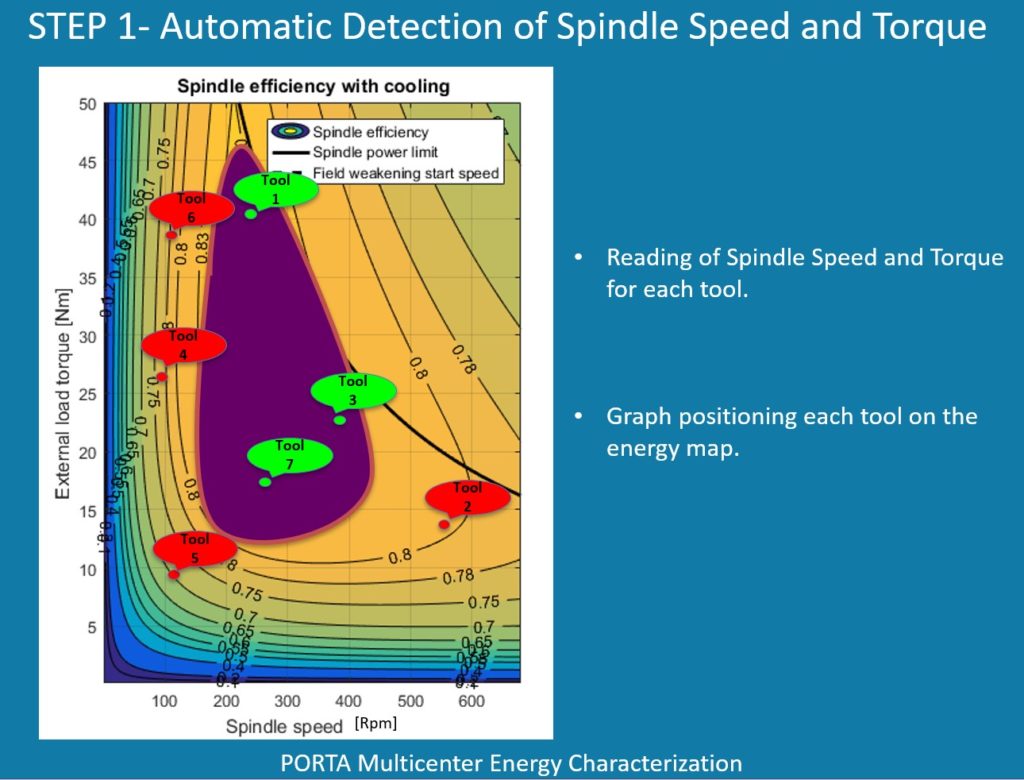

- the Spindle Efficiency;

- Eco Power;

- Map of the Energy Efficiency;

- VibroSync;

- Eco Torque;

- Process Analysis;

- Optimal Acceleration trajectory;

- Algorithms in the Cloud.

Here below, we can see an example of how the efficiency of the spindles is measured, following the above-mentioned points:

The purpose of data extrapolation is precisely to analyze the numerical evolution behind the production of our Machine Tools and the resulting performance they generate for our customers.

It has to be clear to us:

- which figures are important to be analyzed;

- how to interpret them properly;

- which tools are needed to move towards optimization and improvement of these areas and data.

Only the energy efficiency and the right balance of the spindles in production can really generate a great improvement in performance and a strong reduction in energy waste.

If we take this concept and project it into a company that uses so many batteries of Machining Centers, we can understand how, at scale, the control of these aspects can make a big difference.

Industry 4.0 applied on Machine Tools

After having carried out the analysis of the results obtained on the 3-spindle MULTICENTER, we moved to the Assembly Area to show the students what it means to say Industry 4.0 applied in a company that builds Machine Tools.

Today, a 3-spindle Machine Tool made in Porta can guarantee performance in production and optimization of production processes that lead to results never seen before.

A Machine Tool 3 times faster than a single Machining Center and with a CPK coming from just one process, therefore more precise than the classic battery of Machining Centers, whose result comes from the average of 3 processes.

The Continuous Improvement Mindset is the essential basis to best apply the concepts of Industry 4.0, that then becomes an amplifier and positive driver of what technology and artificial intelligence can offer to companies.

The Secret Formula:

LEAN PRODUCTION + INDUSTRY 4.0

We often see companies in our sector far behind technological innovations in some production departments.

We can even see companies in which change is considered as an enemy to be fought and to resist.

And innovation and technology are consequently avoided and ignored in order to stay on the “old-fashioned” working line.

A very underestimated aspect is what in Japan is called “the Continuous Improvement Mindset”.

A Mindset that should be taught in primary schools and that should always go with the development and growth of each company, in all its aspects and departments.

A company that does not grow is a still company

and a still company has a problem, not now,

but soon.

Truth hurts, don’t it? Many people do not accept this way of thinking.

This concept, so ignored, means that even today most production companies do not have a clue of what it means to continue investing, every year, to stay up to date and to face your fierce competitors. In particular, INVESTING:

- in new plants and machinery;

- in new technologies;

- in new types of Machine Tools;

- in personnel training;

- in consultants who know how to support you with the proper strategy and to the right direction.

The results you get will always be directly proportional to how much you expose yourself and if you know how to adapt to change.

And Industry 4.0 is a change that should not be underestimated if we want to be and remain competitive.

For this reason it is essential not only to apply these concepts to your company, but also to choose suppliers of products and services and consultants that are in line with these innovations.

It seems an obvious reasoning, but if you choose a supplier that does not have this attitude and does not apply these concepts first hand, his “ignorance” in terms of innovation will also indirectly affect your performance and your profitability.

Here our Company Mission comes into play to produce and deliver products and services for Machine Tool users who need an extra gear and the support of a partner to get more results in their production departments.

Machine Tools 3 times faster and more efficient

than classic Machining Centers.

For this reason we have decided to develop an area completely dedicated to consulting and training, with courses based on the study of Lean Manufacturing and Industry 4.0.

Specific consultations for our customers directly at their companies, so that we can work together in a collaborative environment, helping users of Machine Tools to achieve above average results.

Are you still convinced that your Machine Tool suppliers and your Lean consultants are really helpful for your company?

Do you want to be supported by partners who can really guide you in a real path of improvement for your production department?

So, if you are a user of Machine Tools and Machining Centers

for manufacturing and metal chip removal,

contact us NOW for a free consultation directly at your company.

We will help you to analyze the efficiency of your production, the scope for improvement and the fleet of machines at your disposal.

Contact us NOW and ask for a FREE consultation

with one of our TECHNICAL TUTORS.

Click here www.flexibleproductionassistance.com to get

more information.

Or contact us at these references

Phone: +39 030-800673

Email: porta@flexible-production.com

If you want to go deeper on the topic of Competitive Production

CLICK HERE

>>> www.flexibleproductionbook.com <<<

My book dedicated to users of Machine Tools who want to make the leap in quality is waiting for you!!!

To your results,

Maurizio Porta

MASTER TRAINER Method PORTA PRODUCTION SYSTEM

Ita

Ita Deu

Deu